- All categories

- Integrated Circuits (ICs)

- Development Boards, Kits, Programmers

- Discrete Semiconductor Products

- Power Supplies - Board Mount

- RF and Wireless

- Sensors, Transducers

- Memory Cards, Modules

- Audio Products

- Circuit Protection

- Crystals, Oscillators, Resonators

- Filters

- Isolators

- Kits

- Maker/DIY, Educational

- Optoelectronics

- Power Supplies - External/Internal (Off-Board)

- Relays

- Resistors

- Test and Measurement

- Uncategorized

- Inductors, Coils, Chokes

- Motors, Actuators, Solenoids and Drivers

- Switches

- Embedded Computers

- Capacitors

- Transformers

- Battery Products

- Products

- All categories

-

Integrated Circuits (ICs)

-

Embedded

- FPGAs (Field Programmable Gate Array)

- Microcontrollers

- CPLDs (Complex Programmable Logic Devices)

- FPGAs (Field Programmable Gate Array) with Microcontrollers

- PLDs (Programmable Logic Device)

- Microcontrollers, Microprocessor, FPGA Modules

- System On Chip (SoC)

- Application Specific Microcontrollers

- DSP (Digital Signal Processors)

- Microprocessors

-

Interface

- Drivers, Receivers, Transceivers

- Sensor and Detector Interfaces

- Analog Switches - Special Purpose

- Analog Switches, Multiplexers, Demultiplexers

- CODECS

- Controllers Interface ICs

- Direct Digital Synthesis (DDS)

- Encoders, Decoders, Converters

- Filters - Active

- I/O Expanders

- Modems - ICs and Modules

- Modules

- Sensor, Capacitive Touch

- Signal Buffers, Repeaters, Splitters

- Signal Terminators

- Specialized

- Telecom

- Serializers, Deserializers

- UARTs (Universal Asynchronous Receiver Transmitter)

- Voice Record and Playback

- Memory

-

Power Management (PMIC)

- DC DC Switching Controllers

- Display Drivers

- Full Half-Bridge Drivers

- Gate Drivers

- LED Drivers

- Motor Drivers, Controllers

- Power Distribution Switches, Load Drivers

- Power Management - Specialized

- Power Supply Controllers, Monitors

- Special Purpose Regulators

- Supervisors

- Voltage Regulators - DC DC Switching Regulators

- Voltage Regulators - Linear

- Voltage Regulators - Linear + Switching

- AC DC Converters, Offline Switches

- Battery Chargers

- Battery Management

- Current Regulation/Management

- Energy Metering

- Hot Swap Controllers

- Laser Drivers

- Lighting, Ballast Controllers

- OR Controllers, Ideal Diodes

- PFC (Power Factor Correction)

- Power Over Ethernet (PoE) Controllers

- RMS to DC Converters

- Thermal Management

- Voltage Reference

- Voltage Regulators - Linear Regulator Controllers

- V/F and F/V Converters

- Specialized ICs

- Audio Special Purpose

- Clock/Timing

- Data Acquisition

- Linear

-

Logic

- Buffers, Drivers, Receivers, Transceivers

- Comparators

- FIFOs Memory

- Flip Flops

- Gates and Inverters

- Gates and Inverters - Multi-Function, Configurable

- Multivibrators

- Shift Registers

- Signal Switches, Multiplexers, Decoders

- Translators, Level Shifters

- Latches

- Specialty Logic

- Counters, Dividers

- Parity Generators and Checkers

- Universal Bus Functions

-

Embedded

-

Development Boards, Kits, Programmers

- Accessories

- Evaluation and Demonstration Boards and Kits

- Evaluation Boards - DC/DC & AC/DC (Off-Line) SMPS

- Evaluation Boards - Expansion Boards, Daughter Cards

- Evaluation Boards - LED Drivers

- Evaluation Boards - Sensors

- Evaluation Boards - Embedded - Complex Logic (FPGA, CPLD)

- Evaluation Boards - Embedded - MCU, DSP

- Programmers, Emulators, and Debuggers

- Software, Services

- Evaluation Boards - Analog to Digital Converters (ADCs)

- Evaluation Boards - Audio Amplifiers

- Evaluation Boards - Digital to Analog Converters (DACs)

- Evaluation Boards - Linear Voltage Regulators

- Evaluation Boards - Op Amps

- Programming Adapters, Sockets

- RF Evaluation and Development Kits, Boards

- RFID Evaluation and Development Kits, Boards

-

Discrete Semiconductor Products

- Power Supplies - Board Mount

-

RF and Wireless

- RF Amplifiers

- Attenuators

- RF Accessories

- RF Demodulators

- RF Detectors

- RF Front End (LNA + PA)

- RF Misc ICs and Modules

- RF Mixers

- RF Modulators

- RF Power Controller ICs

- RF Power Dividers/Splitters

- RF Receivers

- RF Shields

- RF Switches

- RF Transceiver ICs

- RF Transceiver Modules and Modems

- RF Transmitters

- RFID, RF Access, Monitoring ICs

- RFID Transponders, Tags

- RF Multiplexers

- RF Receiver, Transmitter, and Transceiver Finished Units

- RF Antennas

- RFI and EMI - Contacts, Fingerstock and Gaskets

- RFID Reader Modules

- RF Circulators and Isolators

- RF Directional Coupler

- Balun

- Subscriber Identification Module (SIM) Cards

- RFID Accessories

- RFID Antennas

-

Sensors, Transducers

- Current Sensors

- Magnetic Sensors

- Position Sensors

- Specialized Sensors

- Temperature Sensors

- Motion Sensors

- Multifunction

-

Optical Sensors

- Ambient Light, IR, UV Sensors

- Image Sensors, Camera

- Photodiodes

- Distance Measuring

- Photointerrupters - Slot Type - Transistor Output

- Phototransistors

- Reflective - Analog Output

- Reflective - Logic Output

- Photo Detectors - Logic Output

- Photointerrupters - Slot Type - Logic Output

- Photoelectric, Industrial

- Camera Modules

- Photo Detectors - Remote Receiver

- Sensor, Transducer Accessories

- Sensor, Transducer Amplifiers

- Color Sensors

- Encoders

- Encoders - Industrial

- Touch Sensors

- Pressure Sensors, Transducers

- Flow Sensors

- Gas Sensors

- Pressure Sensors, Transducers - Industrial

- Float, Level Sensors

- Magnets

- Proximity Sensors

- Flow Sensors - Industrial

- Humidity, Moisture Sensors

- Memory Cards, Modules

- Audio Products

- Circuit Protection

- Crystals, Oscillators, Resonators

- Filters

- Isolators

- Kits

- Maker/DIY, Educational

-

Optoelectronics

- Circuit Board Indicators, Arrays, Light Bars, Bar Graphs

- Fiber Optic Transceiver Modules

- LED Character and Numeric

- COBs, Engines, Modules, Strips

- Color LED Lighting

- Display Bezels, Lenses

- Fiber Optic Receivers

- Fiber Optic Transmitters - Discrete

- Fiber Optic Transmitters - Drive Circuitry Integrated

- Laser Diodes, Modules

- LED Dot Matrix and Cluster

- LED Emitters - Infrared, UV, Visible

- LED Indication - Discrete

- Lenses

- Optoelectronics Accessories

- White LED Lighting

- Incandescent, Neon Lamps

- Fiber Optic Switches, Multiplexers, Demultiplexers

- Ballasts, Inverters

- LCD, OLED, Graphic

- LCD, OLED Character and Numeric

- Display, Monitor - LCD Driver/Controller

- Power Supplies - External/Internal (Off-Board)

- Relays

- Resistors

- Test and Measurement

- Uncategorized

- Inductors, Coils, Chokes

- Motors, Actuators, Solenoids and Drivers

- Switches

- Embedded Computers

- Capacitors

- Transformers

- Battery Products

- Manufacturers

- Services

- Industries

- Top-Quality Commitment

- Resources

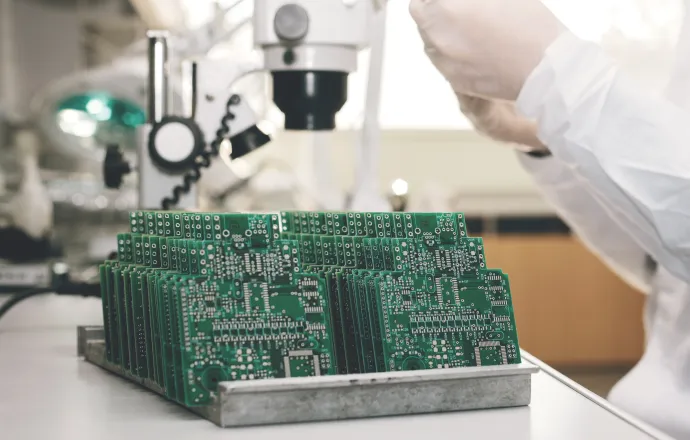

ZERO-TOLERANCE TO COUNTERFEIT ELECTRONIC COMPONENTS

Sourcing

SZC has defined a complete process of the technical management of the supply chain, from the supplier selection and monitoring all the way, through to the inspections and testing techniques aimed to prevent counterfeit components entering the manufacturing line .

LEARN MORE

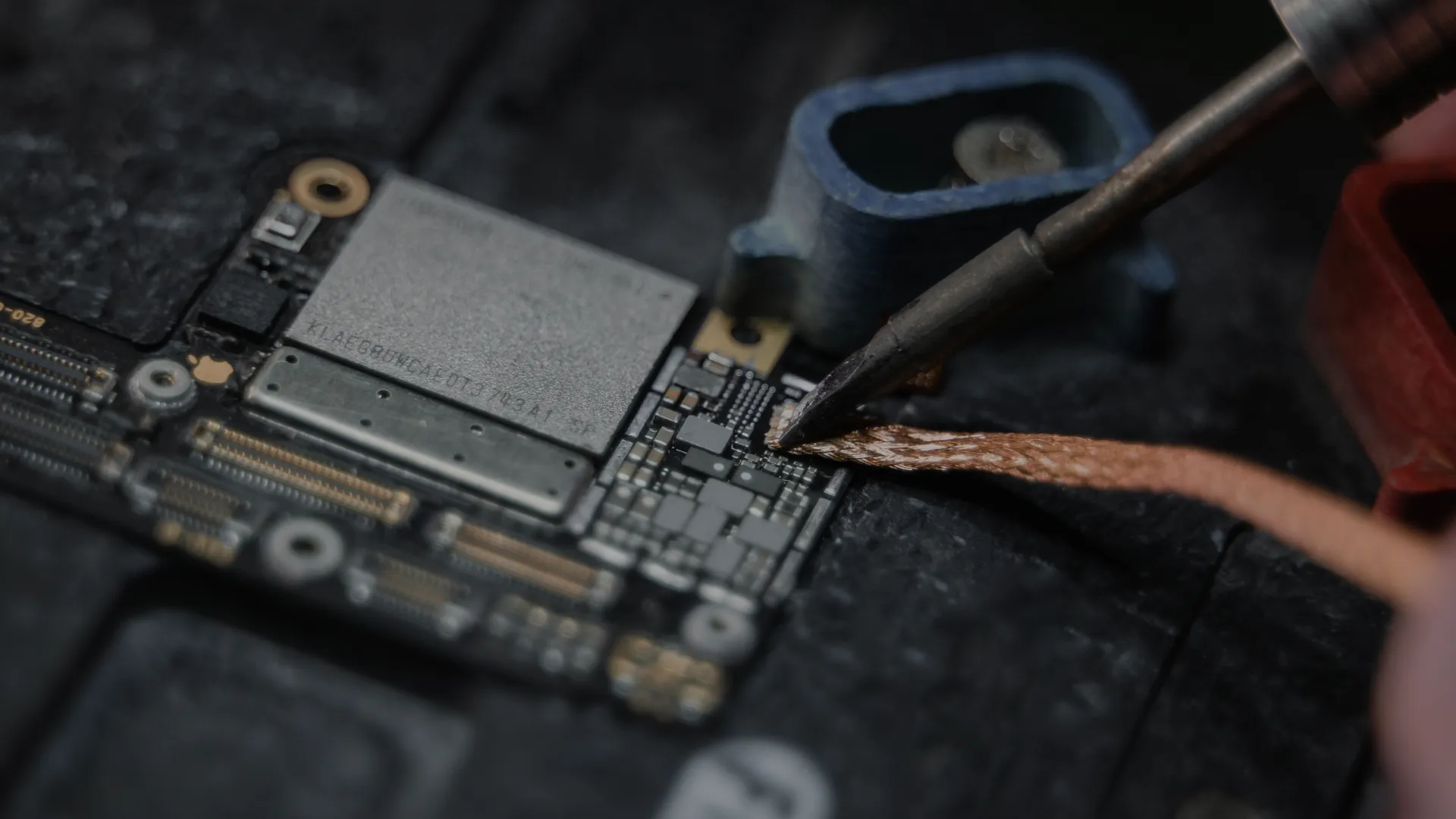

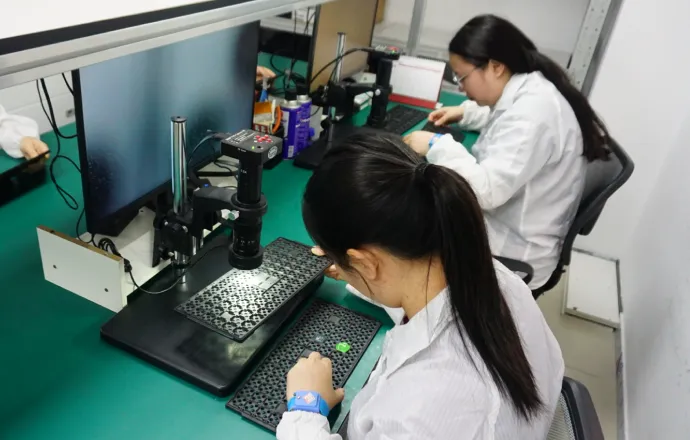

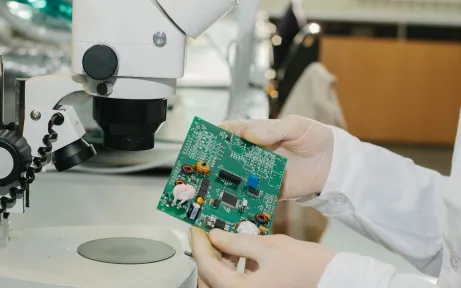

Visual Inspection

SZC's inspectors meticulously use an digital microscope to verify the typing, year and country of origin of the components.

They also check for any re-polishing traces on the surface coating, the condition of the pins, and the manufacturer's logo to ensure the authenticity of the parts.

Visual Inspection Capabilities

Digital Microscopy

SZC's non-destructive and color differentiation available microscopes can detect blacktopping, sanding, oxidation, and re-tinning.

Dimensional inspection

SZC offers inspection systems that recognize 2D characters and ensure that a feature is positioned correctly or in the required dimension.

Maximum Flexibility

Regardless of the components, we develop the optimal inspection solution for each customer. We provide flexibility through freely configurable infeed, outfeed, and item classifications.

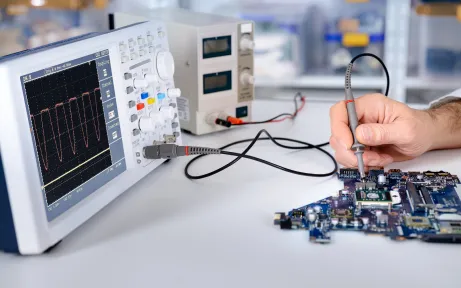

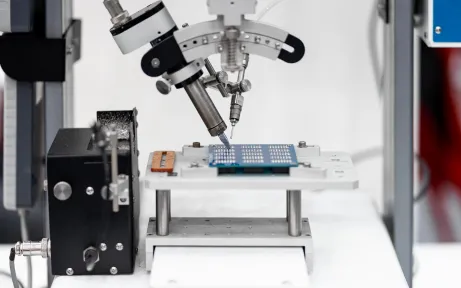

Nondestructive Testing

Non-destructive testing includes an array of inspection techniques that allow inspectors to collect data about a material without damaging it.

These methods are used to detect defects, identify imperfections, the locations of defects or imperfections on the surface of material created.

Nondestructive Testing Capabilities

X-Ray

We use X-ray scanning to identify any internal defects in products. This helps us determine if there are any irregularities such as voids, cracks or other structural abnormalities within the component.

XRF

SZC's XRF machine is a non-destructive analytical technique that can inspect defects, even non-visible ones, inside a sample because of the high penetration of X-rays.

C-SAM

C-SAM acoustic microscopy techniques analyze the intensity and phase of both the reflected and transmitted waves, thereby disclosing internal flaws and defects such as delamination and voids.

Curve Tracer

We perform a failure analysis to determine precisely why an electronic component integrated into a circuit may not operate properly.

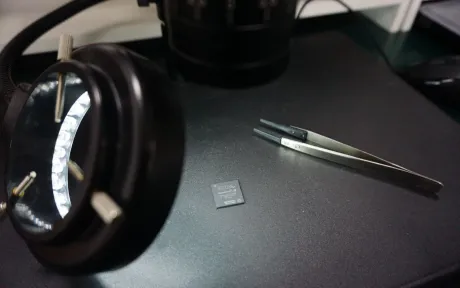

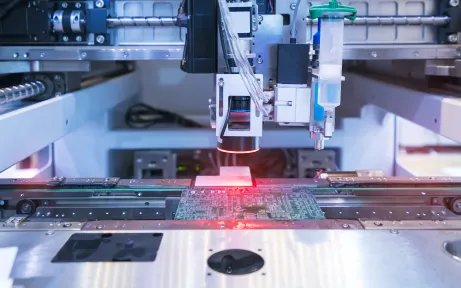

Destructive Testing

Destructive testing is generally conducted before a component enters mass production, such as decapsulation and lead solderability, in order to find the exact point of failure of materials, components, or machines.

Destructive Testing Capabilities

Decapsulation

Decapsulation is used to check its size, the manufacturer's logo, the copyright year, and the wafer code.

Heated Solvent

Through this process, any resurfacing or remarking should have been removed to expose the sanded or possibly original factory surface of the component.

Solderability

We are able to confirm lead integrity of older components using our X-Tronic soldering station or temperature-regulated soldering pot.

Bond Shear

SZC measures bond strengths and distributions to determine whether the bonds meet the required strength standards.

Custom Testing

SZC offers customized authenticity testing services to match our client's unique needs, and we are always delighted to provide further information upon request. Get in touch with us today to learn more about SZC's authenticity-testing services.

VIEW ALL

Schedule a call with a SZC specialist:

Receive a quote from SZC within hours