- All categories

- Integrated Circuits (ICs)

- Development Boards, Kits, Programmers

- Discrete Semiconductor Products

- Power Supplies - Board Mount

- RF and Wireless

- Sensors, Transducers

- Memory Cards, Modules

- Audio Products

- Circuit Protection

- Crystals, Oscillators, Resonators

- Filters

- Isolators

- Kits

- Maker/DIY, Educational

- Optoelectronics

- Power Supplies - External/Internal (Off-Board)

- Relays

- Resistors

- Test and Measurement

- Uncategorized

- Inductors, Coils, Chokes

- Motors, Actuators, Solenoids and Drivers

- Switches

- Embedded Computers

- Capacitors

- Transformers

- Battery Products

- Products

- All categories

-

Integrated Circuits (ICs)

-

Embedded

- FPGAs (Field Programmable Gate Array)

- Microcontrollers

- CPLDs (Complex Programmable Logic Devices)

- FPGAs (Field Programmable Gate Array) with Microcontrollers

- PLDs (Programmable Logic Device)

- Microcontrollers, Microprocessor, FPGA Modules

- System On Chip (SoC)

- Application Specific Microcontrollers

- DSP (Digital Signal Processors)

- Microprocessors

-

Interface

- Drivers, Receivers, Transceivers

- Sensor and Detector Interfaces

- Analog Switches - Special Purpose

- Analog Switches, Multiplexers, Demultiplexers

- CODECS

- Controllers Interface ICs

- Direct Digital Synthesis (DDS)

- Encoders, Decoders, Converters

- Filters - Active

- I/O Expanders

- Modems - ICs and Modules

- Modules

- Sensor, Capacitive Touch

- Signal Buffers, Repeaters, Splitters

- Signal Terminators

- Specialized

- Telecom

- Serializers, Deserializers

- UARTs (Universal Asynchronous Receiver Transmitter)

- Voice Record and Playback

- Memory

-

Power Management (PMIC)

- DC DC Switching Controllers

- Display Drivers

- Full Half-Bridge Drivers

- Gate Drivers

- LED Drivers

- Motor Drivers, Controllers

- Power Distribution Switches, Load Drivers

- Power Management - Specialized

- Power Supply Controllers, Monitors

- Special Purpose Regulators

- Supervisors

- Voltage Regulators - DC DC Switching Regulators

- Voltage Regulators - Linear

- Voltage Regulators - Linear + Switching

- AC DC Converters, Offline Switches

- Battery Chargers

- Battery Management

- Current Regulation/Management

- Energy Metering

- Hot Swap Controllers

- Laser Drivers

- Lighting, Ballast Controllers

- OR Controllers, Ideal Diodes

- PFC (Power Factor Correction)

- Power Over Ethernet (PoE) Controllers

- RMS to DC Converters

- Thermal Management

- Voltage Reference

- Voltage Regulators - Linear Regulator Controllers

- V/F and F/V Converters

- Specialized ICs

- Audio Special Purpose

- Clock/Timing

- Data Acquisition

- Linear

-

Logic

- Buffers, Drivers, Receivers, Transceivers

- Comparators

- FIFOs Memory

- Flip Flops

- Gates and Inverters

- Gates and Inverters - Multi-Function, Configurable

- Multivibrators

- Shift Registers

- Signal Switches, Multiplexers, Decoders

- Translators, Level Shifters

- Latches

- Specialty Logic

- Counters, Dividers

- Parity Generators and Checkers

- Universal Bus Functions

-

Embedded

-

Development Boards, Kits, Programmers

- Accessories

- Evaluation and Demonstration Boards and Kits

- Evaluation Boards - DC/DC & AC/DC (Off-Line) SMPS

- Evaluation Boards - Expansion Boards, Daughter Cards

- Evaluation Boards - LED Drivers

- Evaluation Boards - Sensors

- Evaluation Boards - Embedded - Complex Logic (FPGA, CPLD)

- Evaluation Boards - Embedded - MCU, DSP

- Programmers, Emulators, and Debuggers

- Software, Services

- Evaluation Boards - Analog to Digital Converters (ADCs)

- Evaluation Boards - Audio Amplifiers

- Evaluation Boards - Digital to Analog Converters (DACs)

- Evaluation Boards - Linear Voltage Regulators

- Evaluation Boards - Op Amps

- Programming Adapters, Sockets

- RF Evaluation and Development Kits, Boards

- RFID Evaluation and Development Kits, Boards

-

Discrete Semiconductor Products

- Power Supplies - Board Mount

-

RF and Wireless

- RF Amplifiers

- Attenuators

- RF Accessories

- RF Demodulators

- RF Detectors

- RF Front End (LNA + PA)

- RF Misc ICs and Modules

- RF Mixers

- RF Modulators

- RF Power Controller ICs

- RF Power Dividers/Splitters

- RF Receivers

- RF Shields

- RF Switches

- RF Transceiver ICs

- RF Transceiver Modules and Modems

- RF Transmitters

- RFID, RF Access, Monitoring ICs

- RFID Transponders, Tags

- RF Multiplexers

- RF Receiver, Transmitter, and Transceiver Finished Units

- RF Antennas

- RFI and EMI - Contacts, Fingerstock and Gaskets

- RFID Reader Modules

- RF Circulators and Isolators

- RF Directional Coupler

- Balun

- Subscriber Identification Module (SIM) Cards

- RFID Accessories

- RFID Antennas

-

Sensors, Transducers

- Current Sensors

- Magnetic Sensors

- Position Sensors

- Specialized Sensors

- Temperature Sensors

- Motion Sensors

- Multifunction

-

Optical Sensors

- Ambient Light, IR, UV Sensors

- Image Sensors, Camera

- Photodiodes

- Distance Measuring

- Photointerrupters - Slot Type - Transistor Output

- Phototransistors

- Reflective - Analog Output

- Reflective - Logic Output

- Photo Detectors - Logic Output

- Photointerrupters - Slot Type - Logic Output

- Photoelectric, Industrial

- Camera Modules

- Photo Detectors - Remote Receiver

- Sensor, Transducer Accessories

- Sensor, Transducer Amplifiers

- Color Sensors

- Encoders

- Encoders - Industrial

- Touch Sensors

- Pressure Sensors, Transducers

- Flow Sensors

- Gas Sensors

- Pressure Sensors, Transducers - Industrial

- Float, Level Sensors

- Magnets

- Proximity Sensors

- Flow Sensors - Industrial

- Humidity, Moisture Sensors

- Memory Cards, Modules

- Audio Products

- Circuit Protection

- Crystals, Oscillators, Resonators

- Filters

- Isolators

- Kits

- Maker/DIY, Educational

-

Optoelectronics

- Circuit Board Indicators, Arrays, Light Bars, Bar Graphs

- Fiber Optic Transceiver Modules

- LED Character and Numeric

- COBs, Engines, Modules, Strips

- Color LED Lighting

- Display Bezels, Lenses

- Fiber Optic Receivers

- Fiber Optic Transmitters - Discrete

- Fiber Optic Transmitters - Drive Circuitry Integrated

- Laser Diodes, Modules

- LED Dot Matrix and Cluster

- LED Emitters - Infrared, UV, Visible

- LED Indication - Discrete

- Lenses

- Optoelectronics Accessories

- White LED Lighting

- Incandescent, Neon Lamps

- Fiber Optic Switches, Multiplexers, Demultiplexers

- Ballasts, Inverters

- LCD, OLED, Graphic

- LCD, OLED Character and Numeric

- Display, Monitor - LCD Driver/Controller

- Power Supplies - External/Internal (Off-Board)

- Relays

- Resistors

- Test and Measurement

- Uncategorized

- Inductors, Coils, Chokes

- Motors, Actuators, Solenoids and Drivers

- Switches

- Embedded Computers

- Capacitors

- Transformers

- Battery Products

- Manufacturers

- Services

- Industries

- Top-Quality Commitment

- Resources

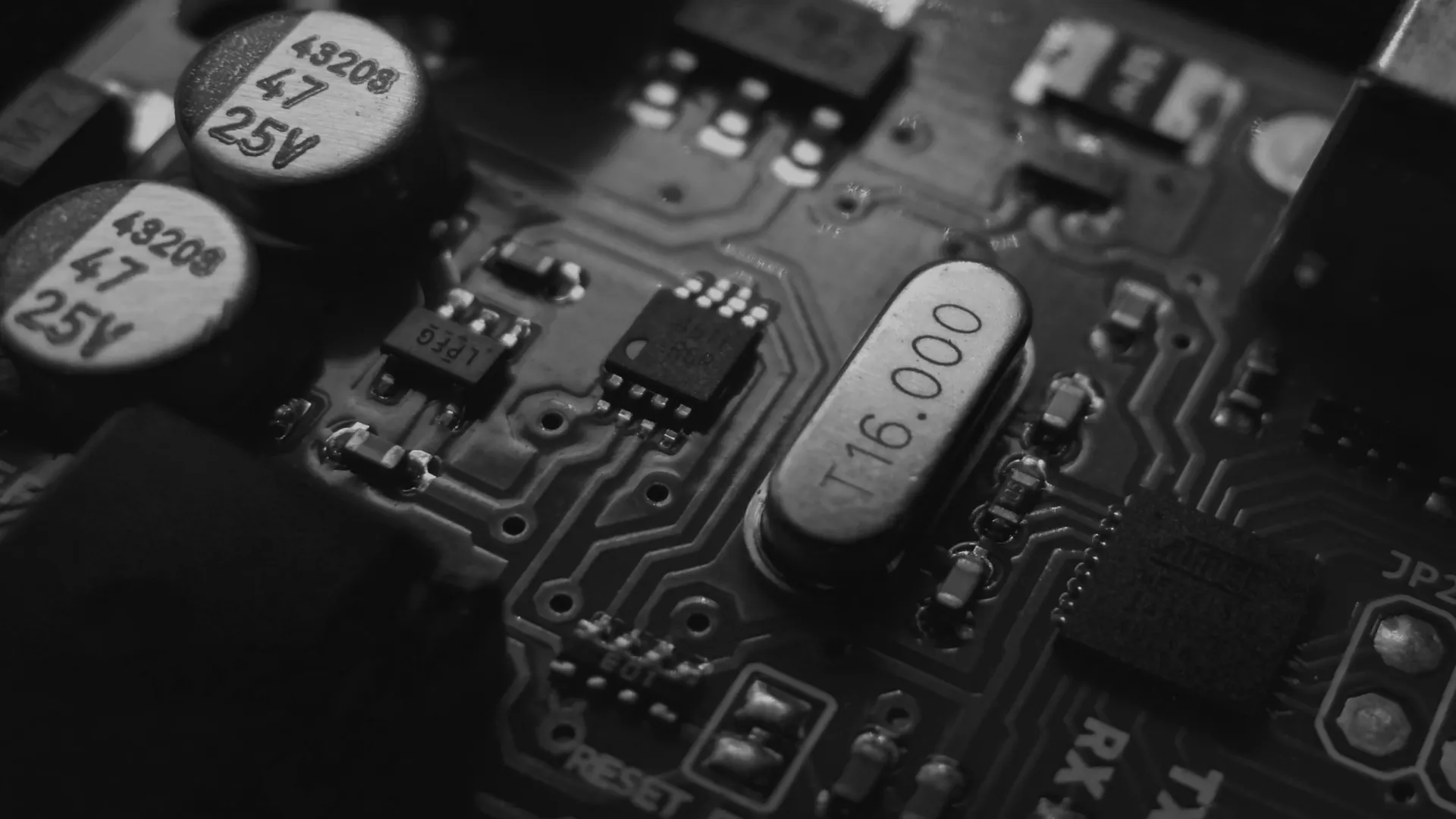

QUALITY IS THE FOUNDATION OF EVERYTHING WE DO

Inspection Process

Inspection Process

Inspection Process

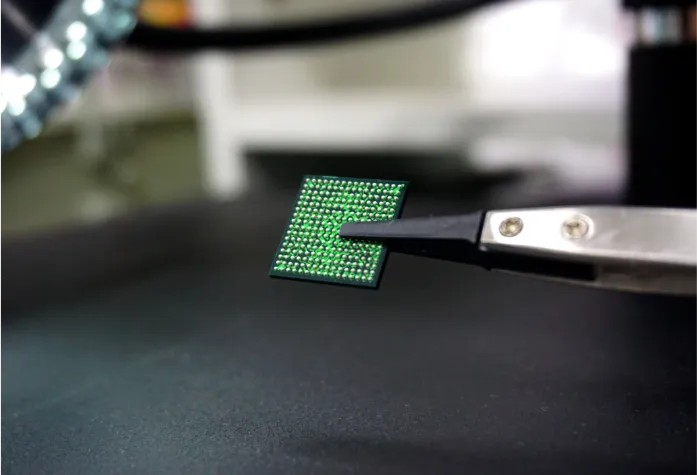

SZC's multi-stage inspection process offers the ultimate solution to prevent the scourge of counterfeit product infiltration into your supply chain. We categorize any product irregularities into discrepant materials and immediately send them back to the vendor. With this commitment to quality, you can rest assured that your supply chain will remain untainted by the perils of fake and fraudulent products.

LEARN MORE Counterfeit Avoidance

Counterfeit Avoidance

Counterfeit Avoidance

Through long-standing relationships and rigorous testing, SZC has never delivered a counterfeit part in our entire history. To mitigate risk, we subject all our products to a rigorous inspection process carried out by personnel with specialized training in counterfeit detection techniques. This dedication to quality and thoroughness ensures that only the most legitimate products make it into our customers' supply chain.

LEARN MORE Vendor Rating Program

Vendor Rating Program

Vendor Rating Program

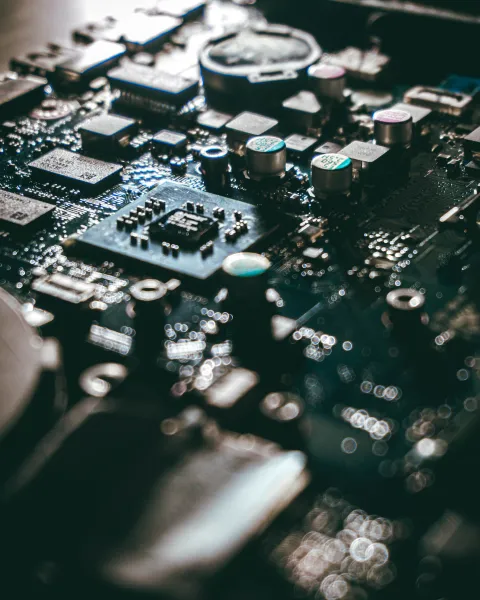

Our ongoing vendor rating program is equally rigorous, ensuring all products are sourced from pre-approved vendors that meet stringent performance standards, industry certification requirements and are equipped with robust counterfeit avoidance measures. We employ both in-house and external testing equipment to guarantee quality, further reinforcing our commitment to the highest standards.

LEARN MORE Certifications

Certifications

Certifications

In a world of non-stop disruption, SZC's unwavering commitment to upholding international quality, environmental, and electronic-industry-specific standards has led to a spate of certifications. These include the ISO 9001:2015 Certified classifications. By demanding such exacting standards, SZC guarantees that all of its globally sourced product has been subjected to rigorous inspection and evaluation.

LEARN MOREProcess for Success

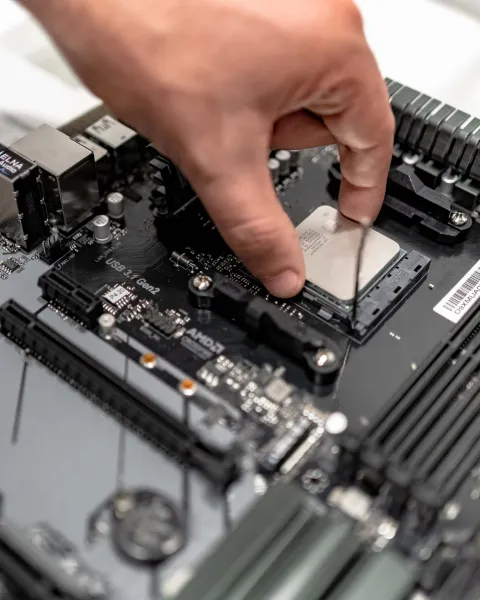

Our inspection quality you can be confident in

We deploy state-of-the-art measures, in-house and through our exclusive partner network, to guarantee that solely bona fide electronic components are allowed into your intricate supply chain and ultimate consumer products.

OPERATIONSVisual Inspection of External Packaging

Document Verification Check

Detailed Visual Inspection

Label Verification

Digital Photography

Requirement Verification

Value-Added Testing

Departs to Customer

Approval

Our dedication to product quality is unwavering

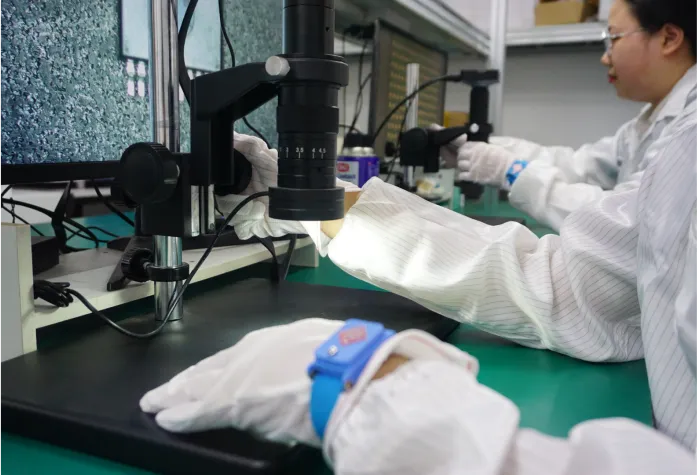

Our team of highly trained quality inspectors are ever-vigilant, constantly staying on the cutting edge of fraud and counterfeit detection and prevention. SZC's rigorous inspection process goes above and beyond your exacting standards.

OPERATIONSExplore our facilities

From our global operational facilities, we have implemented robust environmental controls to ensure your products arrive in pristine condition.

SZC Goes Above And Beyond Industry Standards

Our Industry certifications and affiliations, these standards serve as an assurance that our components and services are worthy of your trust.

VIEW ALL

01

Certified Quality Inspectors

All inspectors in SZC are required to pass the IDEA-ICE-3000 exam and become certified professional inspectors before they may perform final inspection on any product to be delivered to a customer. This certification ensures that our quality team is trained to safeguard and effectively examine components.

02

Engineers

An electronic quality control method’s success can only be ascribed to the quality engineer who created it. Our quality engineers provide the technical expertise necessary to determine the optimal testing techniques for each component type, perform root-cause analysis, and continually improve our operational efficiency.

Recertification and Training

Our commitment to quality runs deeper than just processes and certifications.

Our people receive a wealth of industry and quality knowledge, and through our comprehensive training, we ensure that our people maintain up-to-date skills and knowledge. SZC's global operations employees are required to undergo yearly training refreshers, including MSL and ESD compliance, counterfeit mitigation, and cybersecurity so they can consistently deliver products and services of unparalleled excellence.

Testing

All electronic component testing services and counterfeit detection services are conducted in an ESD 20.20 compliant EPA, and to the highest quality standards.

Functionality Testing

SZC's functionality lab can test the full range of electronic components and peripherals to ensure each component is thoroughly evaluated for quality, capacity, output, value, and more.

LEARN MORE

Authenticity Testing

Our counterfeit detection testing lab is provisioned with the most advanced in-house tools to verify component authenticity. With exterior Inspection, solderability test, X-ray, decapsulation and custom testing solutions available, the integrity of your parts will never be in question.

LEARN MORE