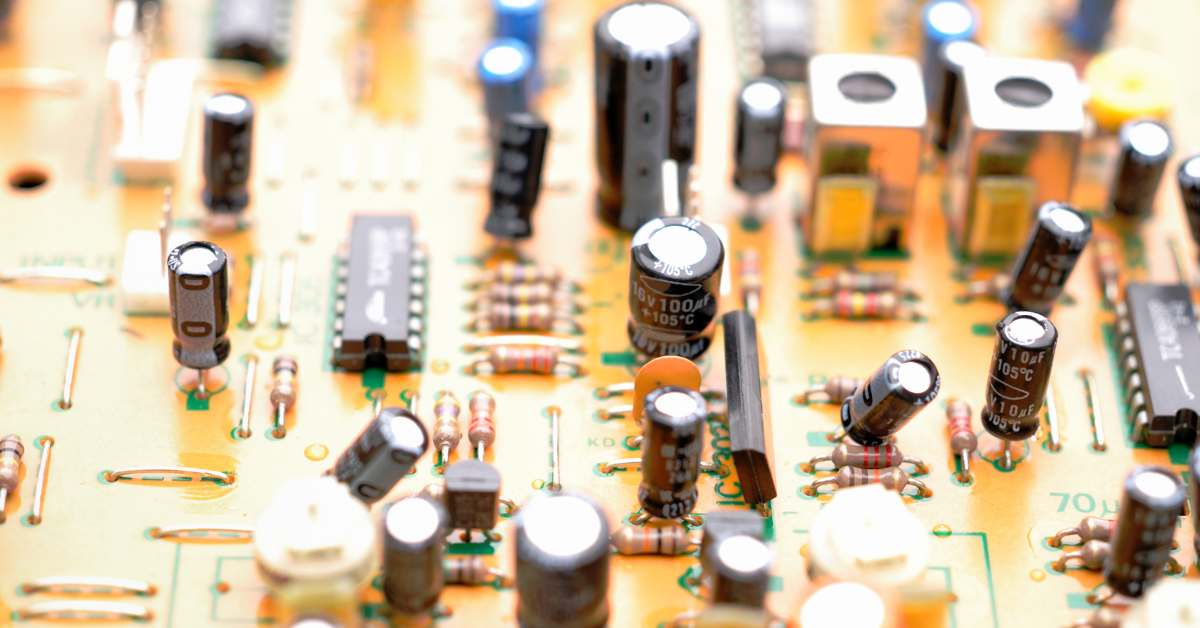

If you've ever worked with electronics or electrical systems, you've probably come across the terms "relay" and "contactor." They're both essential components in various applications, but what sets them apart? In this article, we'll delve into the world of relays and contactors, explaining their functions, differences, and when to use them.

What is a relay?

A relay is similar to an electrical switch that responds to a low-power signal. It serves as a mediator, allowing a small electrical current to control a much larger one. Think of it as the remote control for your TV; when you press a button, it either turns the TV on or off.

How does a relay work?

When a small electrical current flows through the relay's coil (similar to the remote control), it creates a magnetic field, triggering the switch (like the TV). This switch can handle larger electrical loads compared to the original small current.

Common applications of relays

Relays find widespread use in various applications, such as in automotive systems (for turning on headlights), industrial machinery (for controlling motors), and even in household appliances (like the compressor in your refrigerator).

What is a contactor?

In contrast, a contactor,, is like a heavy-duty version of a relay. It's designed to handle high-current applications and is often used in situations where a relay wouldn’t suffice. Picture it as the industrial-grade circuit breaker of the electrical world.

How does a contactor work?

Like a relay, a contactor relies on an electromagnetic coil to control its contacts. When the coil is energized, it either opens or closes its electrical contacts, either allowing or interrupting the flow of electricity to a load.

Common applications of contactors

Contactors find their home in heavy machinery, large HVAC systems, and industrial facilities. They're the go-to choice when dealing with high-power equipment like compressors, pumps, and electric heaters.

Key Differences Between Relays and Contactors

Now that we've got the basics down, let's explore the key differences between relays and contactors.

Control mechanism

Relays are designed for low-power applications and are activated by low-voltage signals,. Contactors, on the other hand, are built for heavy-duty tasks and require higher voltage to operate.

Current-carrying capacity

Relays usually have a current-carrying capacity, typically from a few amperes to around 30 amperes. Contactors, however, can handle much higher currents, ranging from tens to hundreds of amperes.

Common applications

Relays are ideal for tasks that involve moderate current switching, while contactors excel in dealing with high-current loads, ensuring safety and reliability.

When to Use Relays

Relays become handy allies when you want percise control over smaller electrical loads. For example, in your car, relays are used to turn on headlights, activate the horn, or control power windows.

When to Use Contactors

Contactors step in when you're dealing with substantial power requirements. Think of large industrial machines, where you need to switch on motors or control massive electrical heaters. Contactors ensure the smooth operation of your equipment, preventing burntouts.

Advantages of Relays

Energy efficiency

Relays are energy-efficient since they use very little power to remain active. This makes them the preferred option for battery-operated devices and situations where energy conservation is crucial.

Cost-effectiveness

Relays are generally more cost-effective than contactors. They offer a budget-friendly solution for applications that don't involve managing large currents.

Advantages of Contactors

High-current applications

Contactors are the champions of high-current applications. They can handle the load without breaking a sweat, making them indispensable in industrial environments.

Durability

Contactors, built like tanks, are designed for durability. They're rugged and can endure harsh environments, ensuring the smooth operation of your machinery.

Limitations of Relays

While relays are versatile, they do have their limitations.

Limited current capacity

Relays are not suitable for tasks that require extremely high current switching. Attempting to do so in such cases can lead to overheating and malfunction.

Switching speed

Relays operate at slower switching speeds than contactors, which might be a drawback in situations where rapid switching is essential.

Limitations of Contactors

Bulkiness

Contactors are bulky and may not fit well in compact or residential settings where space is limited.

Limited Use in Low Current Applications

Using contactors for low-power applications is impractical and can result in unnecessary expenses .

Why Buy Relays and Contactors from SZComponents?

SZComponents, a trusted electronic component distributor, offers compelling reasons to choose their products:

Extensive Manufacturer Network

SZComponents collaborates with over 1000 electronic component manufacturers, ensuring a wide range of options.

Quality Assurance

Stringent incoming inspection processes guarantee the quality of every component you buy.

Customized Supply Chain Solutions

SZComponents customizes supply chain solutions to meet your specific needs, saving you time and resources.