Have you ever attempted to measure current with a microcontroller? It's a bit like trying to catch a fish in a fast-flowing river – challenging and prone to errors. Unlike voltage, which cooperates smoothly with Analog-to-Digital Converters (ADCs), current measurement adds a layer of complexity that can lead to inaccuracies. This exploration of current measurement nuances will unravel the sources of these errors and introduce a superhero solution: on-chip Analog Core Independent Peripherals (CIPs).

Where Errors Hide

Imagine this scenario: you're working with power electronics, safety systems, or gas monitors, and the task at hand is measuring currents. Here's the catch – high currents make errors more likely. But here's the twist; even small signal measurements can succumb to issues with poor grounding and signal management. If the total errors surpass half of an ADC's Least Significant Bit (LSB), trouble is on the horizon. Let's delve into the origins of these errors.

Revealing the Culprits

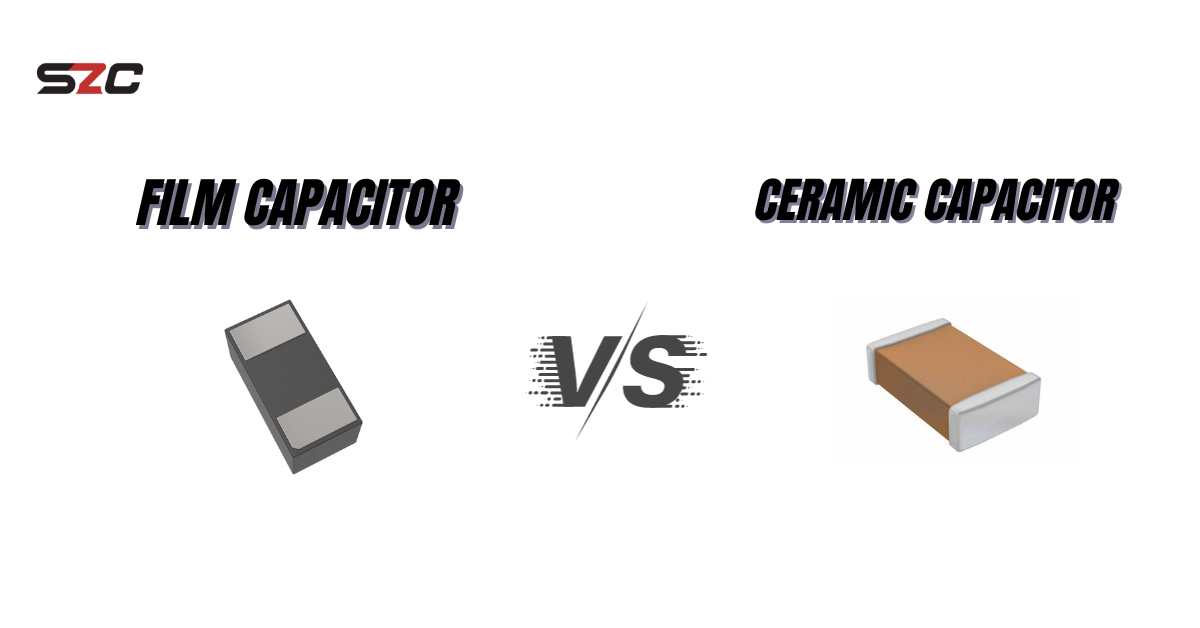

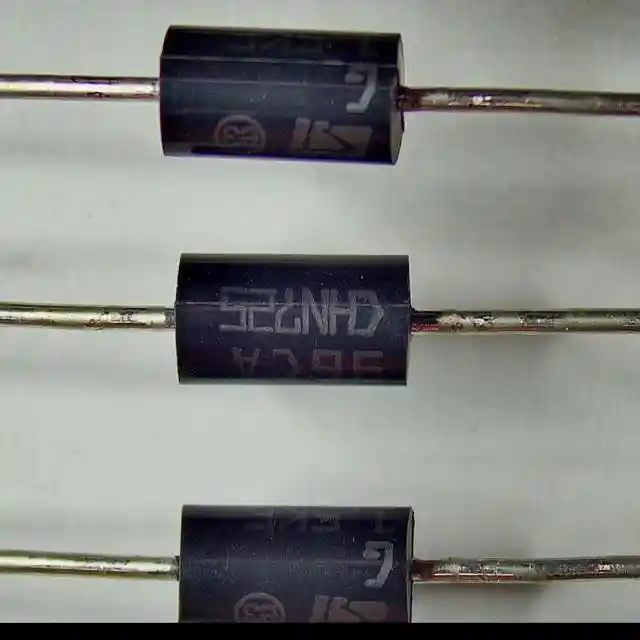

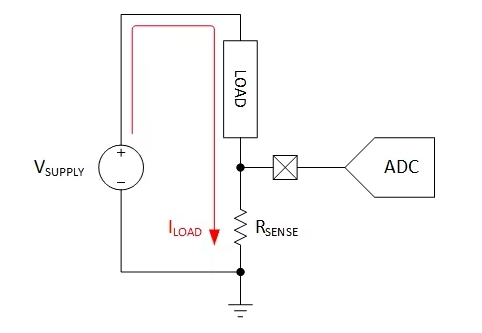

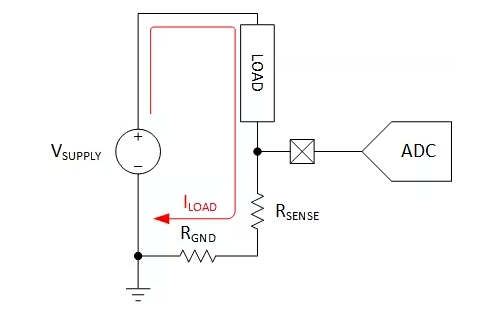

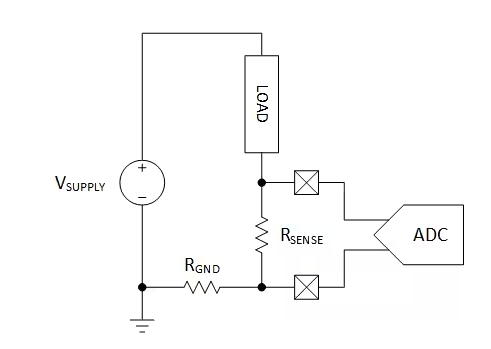

Envision a simple low-side current measurement circuit – the current is flowing, a sense resistor is doing its job, and you're all set to measure. However, enter parasitic elements! Ground return resistance creeps in, adding complexity to the mix. A seemingly minor 10 milliohms can transform a 1-ohm resistor into a finicky 1-ohm, -0%, +2% resistor. The struggle is real, folks.

Navigating the Errors

1. Increasing Shunt Resistance

Sure, you could up the shunt resistance, but in power applications, it's a delicate balance. More resistance means more power dissipation, reducing efficiency – not always the hero in shining armor.

2. Reducing Parasitic Resistance

On the flip side, minimizing parasitic losses is a savvy move. Shorten the current return path, lower impedance – online calculators can guide you. Efficiency cheers in the background.

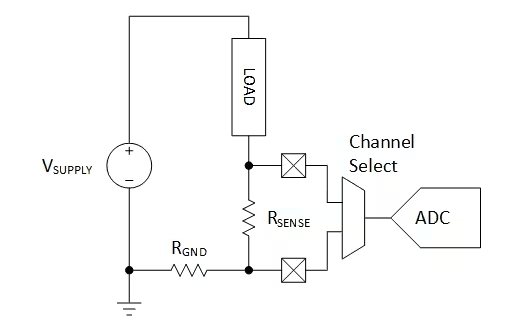

3. Measuring Differentially

Some MCUs have a trick up their sleeves – differential ADCs. They measure voltage difference, not against the MCU's ground. Offset? Conquered. The circuit stays unchanged, and high-side sensing joins the party.

4. Measuring Pseudo-Differentially

No differential ADC? No problem. Introducing pseudo-differential measurement. It's a dance of three steps, correcting for changes between samples. Elegant, isn't it?

5. Calibrating Out Errors

Shift gears to system calibration. Apply known conditions, measure, compute errors, store corrections – a bit of upfront work, but a lifetime of accurate measurements.

Scaling New Heights

The voltage across the current sense resistor isn't always a blockbuster signal. It's more indie. To spotlight it, consider:

1. Using a Programmable Gain Amplifier (PGA)

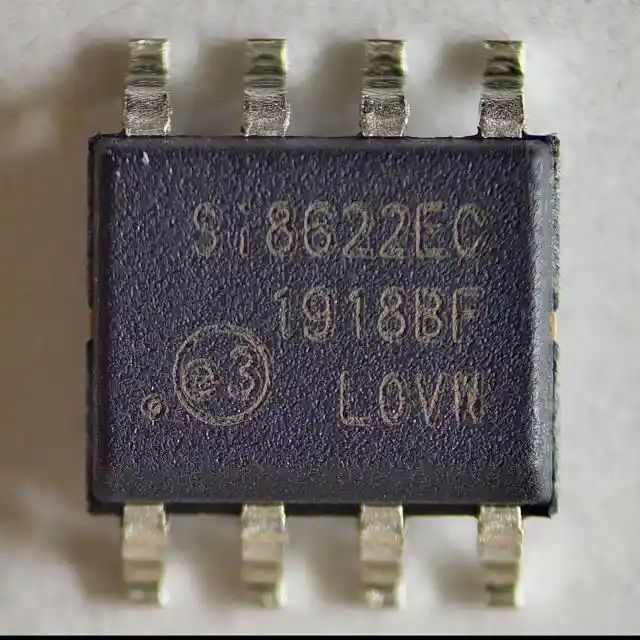

Some MCUs come with a built-in PGA – a savior for small signals. Amplify and conquer, especially when the signal is just a whisper.

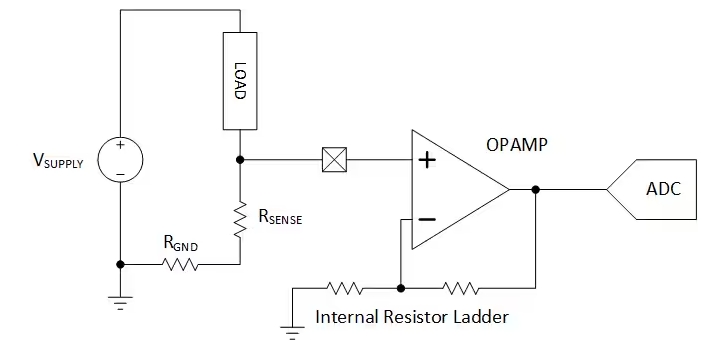

2. A More General Approach

No PGA? No worries. Minimize parasitic resistance, enlist an on-chip Operational Amplifier (OPAMP) CIP. Amplify the output, and if needed, toss in external resistors for a tighter grip on gain.

The Grand Finale

In the MCU realm, measuring current is no leisurely stroll. Armed with insights into these complexities, you're better prepared. For deeper dives into the PIC18F56Q71 family or ATTINY1627 family, our site awaits.