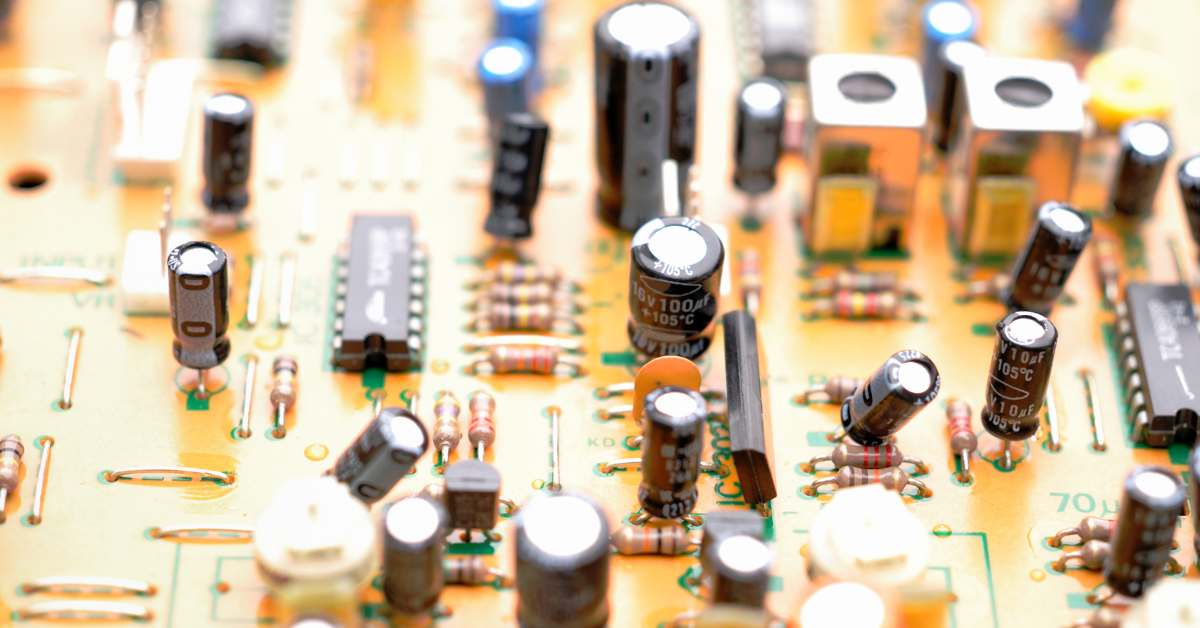

In the rapidly advancing landscape of automation, industries across the spectrum, especially in automotive and manufacturing, heavily rely on precision and efficiency in their operations. Essential to this seamless functionality are motors, which in turn necessitate accurate control, particularly in ascertaining the position and speed of the rotor, usually affixed to the shaft. This is where various technologies, namely optical, magnetic, and inductive sensors, come into play.

Understanding Position Sensing Technologies

Optical Encoders: Precision Meets Fragility

Optical encoders have been a hallmark of precision in position sensing, providing accurate readings. However, their Achilles' heel lies in vulnerability to dirt and contamination. They are relatively expensive and sensitive to the presence of foreign particles, making them less practical in rugged environments.

Magnetic Encoders: A Cost-Effective Trade-Off

Offering a cost-effective solution suitable for high-volume applications, magnetic encoders serve their purpose despite being less accurate compared to their optical counterparts. These sensors are resilient to dirt, although they're susceptible to external magnetic fields common in industrial or automotive settings.

Inductive Encoders: Precision, Affordability, and Robustness

Inductive encoders emerge as a prime solution with superior accuracy compared to magnetic sensors, striking a balance between precision and cost-effectiveness. Their robustness in challenging environments, tolerance to contamination, vibration, and magnetic fields make them an ideal fit for industrial and automotive requirements.

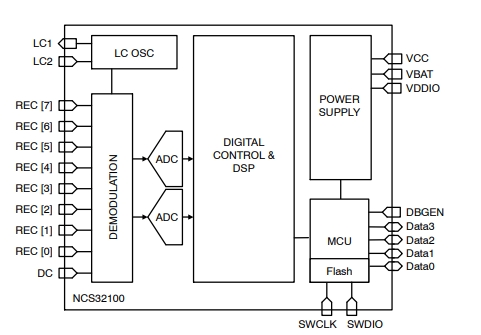

Exploring onsemi’s NCS32100 Dual Inductive Position Sensor

The NCS32100 serves as a comprehensive controller and sensor interface, specifically designed for achieving highly accurate angular sensing solutions in collaboration with a contactless PCB sensor. This versatile device supports a wide range of applications, from static to high-speed operations. With adaptable configuration capabilities, it accommodates diverse inductive sensor patterns and delivers an absolute serial digital output. Inductive sensing, offering distinct benefits such as immunity to contaminants, simplified mechanics, and a more cost-effective sensor solution, sets it apart from traditional position sensors.

Features:

- Delivers Absolute Position Output with Customizable Index

- Provides Velocity, Temperature, and Backup Battery Measurements

- Compatible with an RS-485 Driver (2.5 Mbps)

- Maximum Speed at Full Accuracy: 6000 rpm

- Maximum Speed at Reduced Accuracy: 60,000 rpm

- Operates within a Supply Voltage Range of 2.75 V to 5.5 V

- Allows Interface Level Shifting from 2.7 V to 5.5 V

- Low Power Battery Mode Consumption: 2 mA (Typical)*

- Full Operation Current Consumption: 80 mA (Typical)

- Features an Internal Programmable M0-ARM MCU for Data Interface, Configuration, NVM, and Calibration

- This Device is Pb-Free and RoHS Compliant

Applications:

- Industrial Automation and Robotics

- Motor Control and Positioning

- Servo Applications

Explore More: NCS32100 Datasheet

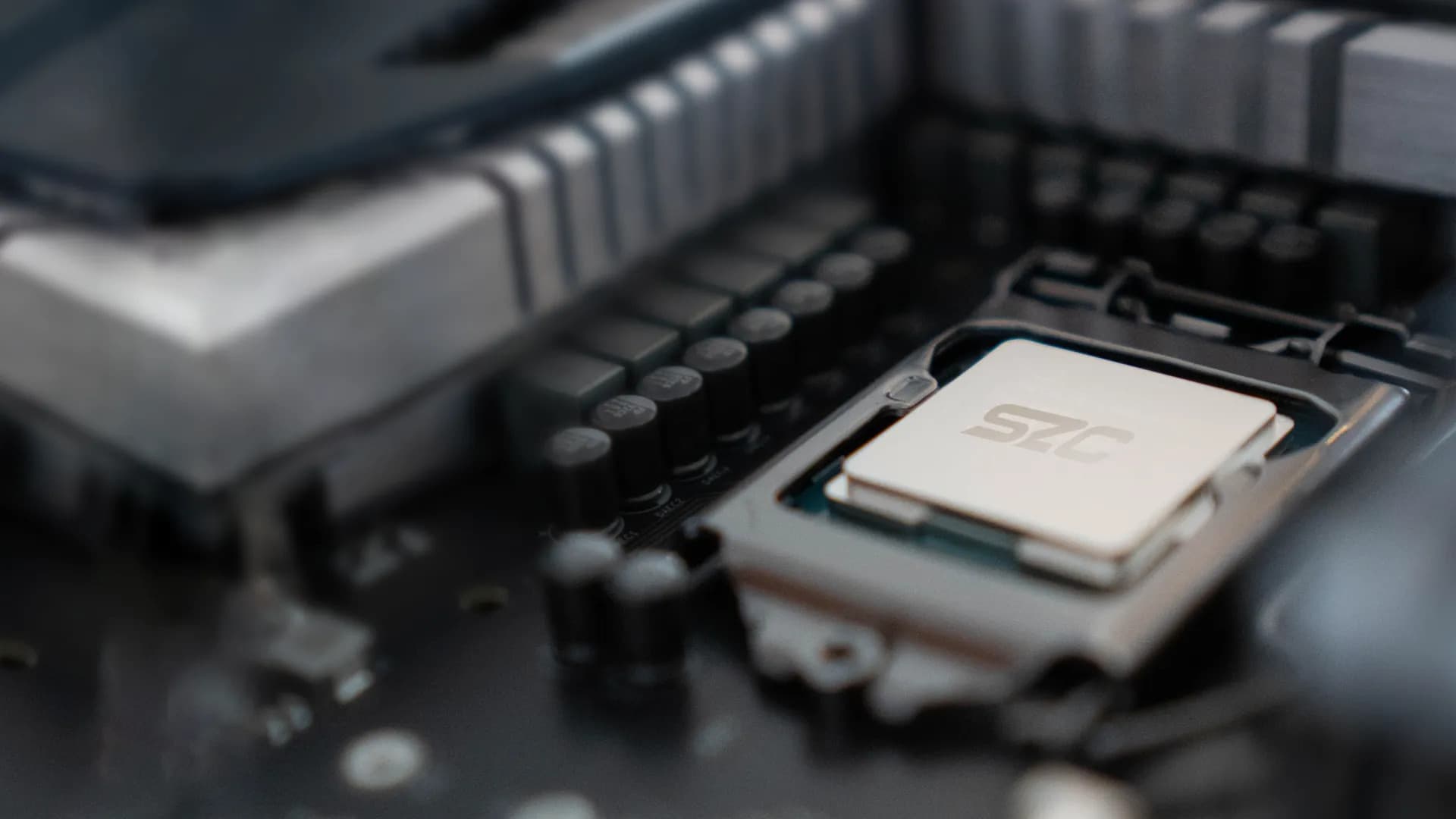

SZComponents: Pioneering Distributor in Inductive Sensors

Alongside the technological advancements in inductive sensors, the role of a reliable distributor like SZComponents plays a vital part in ensuring the availability and quality of these sensors.

SZComponents, with over two decades of experience, has emerged as a prominent electronic component distributor. With a history of collecting 1000 electronic components manufacturers and shipping over 50 million parts, their global sales have surpassed $140 million in the last 5 years.

SZComponents prides itself on continuous learning and growth, sourcing global components, designing customized supply chain solutions, and employing strict incoming inspection mechanisms for testing.

Conclusion

In summary, onsemi's inductive position sensors, the NCS32100 represent a leap forward in sensor technology, revolutionizing both industrial and automotive applications. Their unparalleled precision, reliability, and adaptability, coupled with the assurance of SZComponents' distribution, serve as the cornerstone in the era of automation, promising advancements that transcend traditional sensor capabilities.